KE:S

Der Name

Ke:s ist Käse auf Vorarlbergerisch (Vorarlbergerisch – deutsches Wörterbuch). Ich mache Vorarlberger Alpkäse, der eine besondere Form des Vorarlberger Bergkäses ist, nämlich solcher, der auf der Alpe (Deutsch: Alm) gemacht ist. Ich heiße Anton.

Anton macht Ke:s

Der Ke:s, den ich mache, der Ke:s, den ich anbiete, ist ein gepsenkäse as dem Bregenzerwald.

01

Gebsen

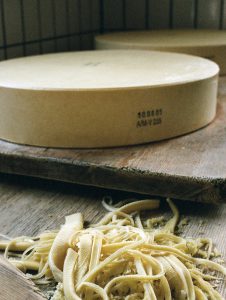

‚Gebsen‘ sind niedrige, 10-12 cm hohe und sehr weite Holzfässer mit ca. 60 cm Durchmesser. Das Käsemachen beginnt mit dem Melken am Abend. Die Abendmilch wird frisch und kuhwarm in die Gebsen gefüllt. In der warmen, ungekühlten Milch können sich die verschiedenen Arten von Milchsäurebakterien, die in der Milch vorhanden sind, vermehren. Das heißt, dass die Milch über Nacht reift.

02

Am Morgen

Abgeschöpft. Beim Abrahmen kann der Senn (als Senn wird in Vorarlberg ausschließlich derjenige bezeichnet, der den Käse macht) die Milch probieren. Je nach Wetter und Weidegang der Kühe entwickelt sich die Milch anders. Wenn es heiß oder schwül ist, ist die Milch stärker gereift als wenn es kalt ist. Auf den jeweiligen Zustand der Milch muss ich beim weiteren Prozess des Käsemachens reagieren. Die Milch ist aber in jedem Fall in den Gebsen so gereift, dass ich auf Bakterienkulturen, die aus dem Labor kommen, vollständig verzichten kann.

Der große Vorteil von ‚Gebsen‘-gereifter Milch ist die natürliche Artenvielfalt an Milchsäurebakterien, die sich so in der Milch entwickeln können. Diese Vielfalt führt im Laufe des Reifeprozesses des Käses zu einem sehr breiten und sehr individuellen Geschmack der einzelnen Käselaibe, was sich immer mehr bemerkbar macht, je länger ein Käse gereift ist. Die Vielfalt des Lebens in der Milch kann sich immer mehr entfalten. Die abgerahmte Milch aus den ‚Gebsen‘ wird in die beiden Kupferkessel, von denen der große 1200 Liter, der kleine 600 Liter fasst, geleert und auf 32°C gewärmt.

Die Milch, die am Morgen gemolken wird, kommt frisch dazu. Je nach Wetter bzw. je nach Reifezustand der Milch bleibt diese kürzer oder länger bei 32°C stehen. Das ist die ideale Temperatur für das Wachstum der Milchsäurebakterien. Wenn es kalt ist, bleibt die Milch länger bei 32°C stehen, damit sie sich noch entwickeln kann. Wenn es heiß ist kürzer, damit sie nicht überreif wird. Danach wird das Lab (‚Renne‘, wie es im Bregenzerwald heißt) eingerührt.

03

Renne

Vom Metzger bekomme ich getrocknete Labmägen von Kälbern. Diese lege ich für 24 Stunden in die Molke ein. Der Magen gibt dann die Enzyme, die für die Milchgerinnung verantwortlich sind, an die Molke ab. Der Magen wird wieder herausgespielt und die Molke mit den nun enthaltenen Enzymen ist die Renne.

Mit einem Liter Renne gerinnen 1000 Liter Milch innerhalb einer halben Stunde zu einem schönen Gallert. Die Renne ist außerdem wichtig für die Reifung des Käses und wirkt wie eine Kultur. Wenn die Milch dick geworden ist, wird sie mit einer Harte geschnitten. Mit dem richtigen Schwung, damit ein schöner gleichmäßiger Käsebruch entsteht.

Beim Schneiden trennt sich der Käse von der Molke und beginnt als Bruch in der Molke zu schwimmen. An der Art, wie sich beim Schneiden die Molke vom Käse trennt, am Geruch, der dabei aufsteigt und an der Farbe der Molke kann der erfahrene Senn erkennen, ob in der Reifeentwicklung alles in Balance ist und wie er weiter reagieren muss.

„

Auf der Alpe

stelle ich selbst

die ‚Renne‘ her.

“

Der Käse wird dann zirka 1,5 Stunden gerührt und dabei auf 52°C aufgeheizt. Wenn der Käse denn rösch ist – wenn sich eine Handvoll Käse, gepresst zu einem Ball, gut verreiben lässt – wird er mit einem großen Käseleinen, das man über einen biegsamen Metallstab hängt, aus dem Kessel geholt. Aus dem großen 4, aus dem kleinen 2 Laibe. Diese werden in Runde, in der Größe verstellbare Formen gedrückt, mit einem Holzdeckel zugedeckt und gepresst. Anfangs mit wenig Druck, dann mit immer mehr, damit die Molke gut heraus rinnen kann.

04

Am nächsten Morgen

Am nächsten Morgen sind die Käse fertige Laibe geworden, die noch weich und Gummi sind. Sie kommen dann für 3 Tage in ein Salzbad. Darin nehmen sie Salz auf und dabei kommt es zu einem wichtigen Austausch von Spurenelementen. Vom Salzbad werden die Laibe in die Regale gelegt, wo sie der weiteren Pflege harren und heranreifen.

Zurück zum Kessel: Wenn der Käse ausgenommen ist, bleibt die Molke im Kessel zurück. 10% der Milch wird zu Käse, der große Rest ist Molke. Diese Molke wird nun weiter aufgeheizt, bei ca. 85°C steigt Fett, Bruch genannt, auf. Dieser Bruch wird mit der Bruchkelle abgeschöpft, gekühlt und gemeinsam mit dem Rahm, der am Morgen von den Gebsen abgeschöpft wurde, zu Butter gerührt. Kurz vor dem Kochen wird etwas gesäuerte Molke in den Kessel geleert und die Sennsuppe, das Resteiweiß, steigt auf. Im frischen Zustand ist die Sennsuppe die tägliche Vorspeise auf der Alpe.

05

Die Sennsuppe

Aus der Sennsuppe wird auch der sogenannte ‚Ziger‘ hergestellt: Dazu lässt man sie in Tüchern abtropfen und würzt sie dann neben Salz und Kümmel mit dem ‚Zigerkraut‘, welches einen sehr speziellen, intensiven und unverwechselbaren Geschmack verleiht. Wenn die Sennsuppe abgeschöpft ist, bleibt die klare Molke, ‚Schotte‘ genannt, übrig. Diese braucht man, um die Gebsen darin zu waschen. Wäscht man sie lediglich mit Wasser, würden sie schmierig und unbrauchbar werden.

Je nach Wetter werden die Gebsen unterschiedlich gewaschen. Bei Kälte dreht man sie kurz in der Molke und brüstet sie, damit sich im Holz der Gebsen etwas bakterielles Leben erhalten kann, das dann die Milchreifung über Nacht belebt. Wenn es jedoch heiß und schwül ist, bleiben die Gebsen länger in der heißen Schotte liegen und werden stärker gebürstet, damit die Reifung etwas gebremst wird. Das Gebsenwaschen über dem dampfenden Kessel ist die tägliche Sauna des Sennen.

06

Zum Schluss

Danach kommt die Molke zu den Schweinen, die sich jeden Tag aufs Neue darauf freuen. Dann wird noch der Kessel geschrubbt, die Käselaibe noch einmal gewendet, der Boden geschwemmt und gebürstet. Dann kehrt für ein paar Stunden Ruhe ein, bis die frisch gemolkene, kuhwarme Milch wieder in die Gebsen geleert wird.

07

Je länger ein Käse gereift ist, desto deutlicher wird, wie gut dies gelungen ist

Wenn auf diese Weise, unter Verwendung von ‚Gebsen‘, Käse gemacht wird, braucht es die volle Aufmerksamkeit des Senns. Der Prozess ist ein sehr lebendiger und jeden Tag etwas anders. Das Lebendige bleibt immer überraschend, es gibt uns immer wieder Rätsel auf und birgt Geheimnisse. Es obliegt der Sensibilität und Erfahrung des Senns, die Zeichen zu lesen, den Prozess geschehen zu lassen und ausgleichend einzugreifen.